Insights into Polystyrene Foam: Dynamics and Growth Factors

|

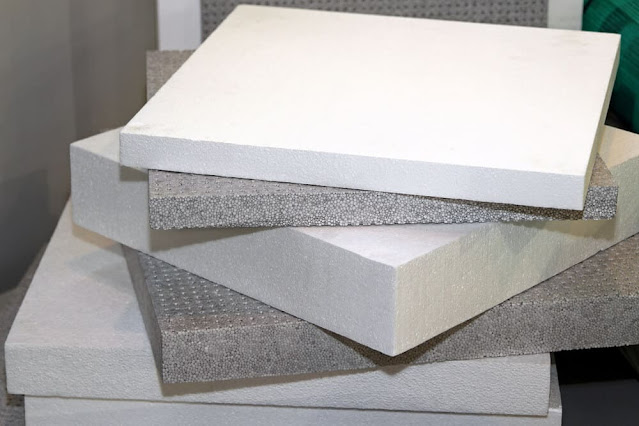

| Polystyrene Foam |

Polystyrene foam, commonly known as Styrofoam, is a ubiquitous material with diverse applications across industries. From packaging to construction, polystyrene foam plays a crucial role in modern manufacturing. Understanding the dynamics and growth factors driving the demand for polystyrene foam is essential for stakeholders in the industry. Let's delve into some key insights into the dynamics and growth factors shaping the polystyrene foam industry.

Dynamics:

The Polystyrene Foam is influenced by various factors, including space capsule technological advancements, regulatory policies, and consumer preferences.

Rapid industrialization and urbanization have fueled the

demand for polystyrene foam in construction and infrastructure development

projects worldwide.

Fluctuations in raw material prices, particularly the cost

of styrene monomer, can impact the profitability and competitiveness of

polystyrene foam manufacturers.

Growth Factors:

The versatility and cost-effectiveness of polystyrene foam make it a preferred choice for packaging applications across diverse industries, driving growth.

Technological innovations in manufacturing processes have

led to the development of lightweight, durable, and high-performance

polystyrene foam products, expanding their applications in automotive,

aerospace, and marine sectors.

Rising environmental concerns and regulations aimed at

reducing plastic waste have spurred demand for eco-friendly alternatives to

traditional polystyrene foam, such as bio-based foams derived from renewable

sources.

Segmentation:

The polystyrene foam can be segmented based on product type, application, and end-user industry. Common product types include expanded polystyrene (EPS) and extruded polystyrene (XPS), each offering unique properties and applications.

Major application segments for polystyrene foam include

packaging, insulation, cushioning, and disposable food service products.

End-user industries driving demand for polystyrene foam

include construction, packaging, automotive, electronics, and healthcare.

Regional Trends:

The Asia-Pacific region dominates the global polystyrene foam , driven by rapid industrialization, urbanization, and infrastructure development in countries like China and India.

North America and Europe also contribute significantly

to growth, with demand driven by the

construction, packaging, and automotive industries.

Emerging economies in Latin America, the Middle East, and

Africa present untapped opportunities for polystyrene foam manufacturers,

supported by growing construction and packaging sectors.

Future Outlook:

Despite challenges such as environmental concerns and regulatory pressures, the polystyrene foam is expected to witness steady growth driven by expanding applications and technological advancements.

Continued investments in research and development, along

with a focus on sustainability and innovation, will be crucial for

manufacturers to maintain competitiveness and capitalize on emerging

opportunities in the global polystyrene foam

.

Collaboration among industry stakeholders, policymakers, and

environmental organizations will play a vital role in addressing sustainability

concerns and shaping the future of the polystyrene foam industry.

Insights into the

dynamics and growth factors provide valuable perspectives for

understanding the trajectory of the polystyrene foam industry. As the continues to evolve in response to changing

consumer preferences and regulatory requirements, stakeholders must remain

vigilant and adaptable to navigate challenges and capitalize on opportunities

for growth and innovation.

Get more insights on This Topic- Polystyrene Foam

Comments

Post a Comment